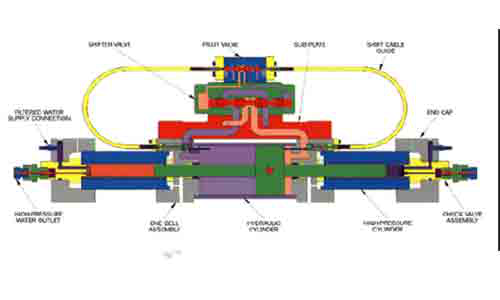

Waterjet cutting is based on the principle of high pressure. The ratio of water pressure to oil pressure is 20:1. Normally, the water pressure is 380MPa and the oil pressure is 19MPa. There are generally two oil seals for each intensifier pump, both of which are installed in the cylinder end bell of the intensifier, which are called high pressure oil seals. When you see oil leaking from the inspection hole of the cylinder end bell, please replace the high pressure oil seal in time. When you see the gap between the cylinder end bell and the cylinder, or if there is oil leakage from the detection hole between the cylinder and the cylinder end bell, please replace the mortgage O-ring on the cylinder end bell in time. High pressure oil seals generally work six months to one year. This depends on the quality of water and oil. When customers use water cutting equipment, they should frequently replace the water filter element and observe the state of use of the oil filter element, and add two iron magnets to the oil tank , so that the metal impurities inside will be adsorbed on the magnet. For more knowledge points about maintaining waterjet cutting equipment, please contact us, we will give you all the maintenance waterjet cutting methods.

Merci de renseigner vos informations et nous vous répondrons dans les plus brefs délais..